These envelopes make retrieving and recording information very easy.

Usually, promotional material is printed on the perforated reply slip flap, which can then be filled in and returned inside the envelope once completed.

Bangtail envelopes are widely used by charities and fundraising organizations to facilitate the collection of donations, where the design can be useful for protecting the privacy of the donor’s details.

There are two styles of Bangtail envelopes:

1. The bangtail ‘flap’ has its reply slip attached to the flap of the envelope.

2. The bangtail ‘back’ has a reply slip attached to the back panel of the envelope.

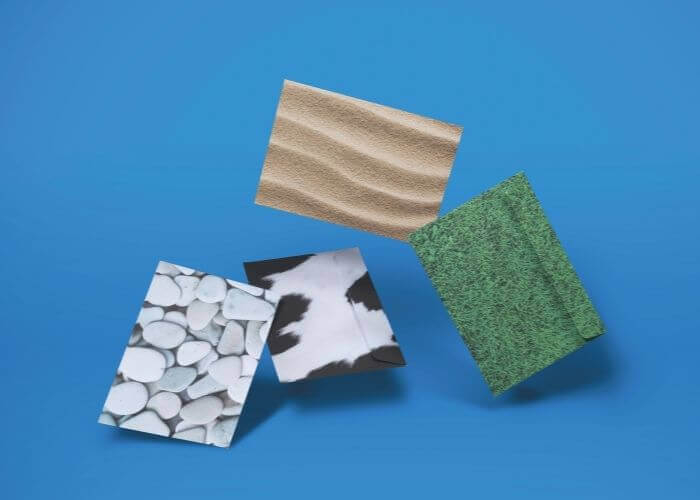

Black

Black Purple

Purple Blue

Blue Red

Red Green

Green Yellow

Yellow Grey

Grey White

White Pink

Pink Cream

Cream Brown

Brown Navy

Navy Violet

Violet Lime

Lime Orange

Orange